Sharing Ideas

at mechanical news

To stay current with the frequently changing HVAC industry is a challenge that we accept in order to fulfill our mission. It is our duty to help as best as we can, so that is why we want you to stay up-to-date with everything as well. Check out the various news articles, industry tips and AT Mechanical updates!

Strength Comes Not From Size But From Utilizing a Flexible and Dynamic Approach The HVAC industry is constantly changing, improving, and evolving. With a company culture that is collaborative and client-focused, AT Mechanical has been able to achieve success and growth, continuing to gain the trust and respect of those in the industry. As a full-service HVAC mechanical design contractor, AT Mechanical has differentiated itself from competitors by eliminating mistakes, focusing on being flexible and dynamic, utilizing forward-thinking systems and solutions and providing the best technology, resources, and tools to the team. To read the article featuring AT Mechanical, please visit SMACNA Greater Chicago .

Press Release: Brian Pannier Promoted to General Manager AT Mechanical is proud to announce the promotion of Brian Pannier to General Manager. Brian has been with AT Mechanical for three years and has been instrumental in the development of our project management process. He will be a great asset to the leadership team here and will continue to work as our project management lead as well as becoming a stronger liaison between our field, our office and our customers. During his time with AT Mechanical, Brian has implemented and streamlined protocols which have improved efficiency in and around our company and has frequently been the force behind helping our jobs run smoothly. Please join us in congratulating Brian in his new role, as we continue to work together as a team to consistently provide the best value to our customers through innovation, low overhead, high productivity and expertise. Congratulations Brian!

Elevated Work platforms are a valuable tool for working at heights, but with any machinery they must be used correctly and safely at all times. You must operate within the manufacturers specifications, be trained properly, inspect your elevated work platform per shift, operate controls before use as a safety check, and understand emergency override controls which should be at ground level and practiced in the field. Work areas must be checked before beginning any job for hazards such as drop offs, inclines, holes, and debris; untamped earth fills and overhead obstructions such as power lines or service drops. It is extremely important to thoroughly inspect your elevated work platform before using, as well as keep a written log of your per shift inspection. Inspect for loose parts, cracked welds, damaged or frayed wire rope, improper adjustments and broken safety devices such as horns, emergency controls, and gates. Check the frame, brakes, and tires for signs of damage or wear and tear. Before moving or raising the platform of an elevated work platform, make sure that it's placed on a level, firm surface. Have outriggers or stabilizers properly positioned and ensure all platform guardrails are properly installed. Additional tips: Keep an eye on ropes, cords, and hoses at the jobsite to ensure they don't get tangled up in the work platform. Load the platform evenly and be careful not to overload it. Follow the manufacturer's instructions regarding loading. Never put the operator in the position of being trapped between the platform and the structure being worked on. Keep the area clear of other workers when the platform is being moved, raised or lowered.

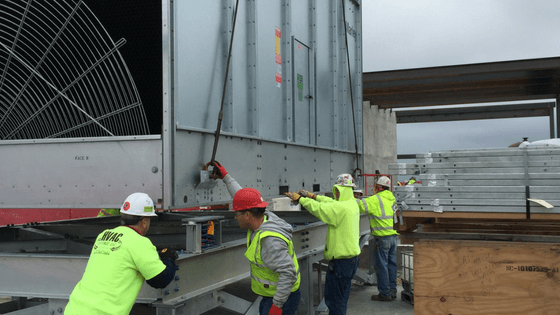

Studio Gang was looking to achieve true occupant comfort with a highly efficient system In 2013, Studio Gang was looking to grow and expand their operations, and purchased the old Polish National Alliance building, converting it into a City of Chicago Landmark building. When it came time to consider how best to approach the HVAC for the building, it was important to preserve the building's Landmark status as well as to make decisions based on sustainability. Alex Tompsidis, president of AT Mechanical was called in to conduct the search for an HVAC system. Always focusing on the customer's needs, Tompsidis recognized the importance of "balancing money and quality. In terms of quality, comfort comes first. Ultra-quiet operation is also a key criterion, along with indoor air quality, maintainability and reliability of the equipment." To read the article featuring AT Mechanical, please visit NAESCO.org .